Zida za carbide zopangidwa ndi simenti zimatchuka kwambiri mu zida zomangira za CNC. M'mayiko ena, zida zozungulira zoposa 90% ndi zida zopitirira 55% zimapangidwa ndi carbide yopangidwa ndi simenti. Kuphatikiza apo, carbide yopangidwa ndi simenti imagwiritsidwa ntchito popanga zida wamba monga zobowolera ndi zodulira nkhope. Kugwiritsa ntchito carbide yopangidwa ndi simenti kukuwonjezekanso mu zida zovuta monga zoyeretsera, mphero zomaliza, zodulira zamagetsi zapakati ndi zazikulu zomangira mano olimba, ndi zomangira. Kudulira bwino kwa zida za carbide zomangidwa ndi simenti ndi kuwirikiza kasanu mpaka kasanu kuposa zida zachitsulo champhamvu (HSS). Kuchuluka kwa chitsulo chomwe chachotsedwa pa unit ya tungsten kuli pafupifupi kasanu kuposa kwa HSS. Chifukwa chake, kugwiritsa ntchito kwambiri carbide yopangidwa ndi simenti ngati chida ndi njira imodzi yothandiza kwambiri yogwiritsira ntchito zinthu moyenera, kupititsa patsogolo zokolola, ndikuwonjezera phindu lazachuma.

Kugawa Zida za Simenti ya Carbide

Kutengera kapangidwe ka mankhwala akuluakulu, carbide yopangidwa ndi simenti ingagawidwe m'magulu awiri: carbide yopangidwa ndi simenti yokhala ndi tungsten carbide ndi carbide yopangidwa ndi titanium carbonitride (Ti(C,N)), monga momwe zasonyezedwera mu Table 3-1.

Carbide yopangidwa ndi simenti yochokera ku Tungsten carbide imaphatikizapo:

Tungsten-cobalt (YG)

Tungsten-cobalt-titanium (YT)

Ndi ma carbide osowa (YW) owonjezeredwa

Mtundu uliwonse uli ndi ubwino ndi kuipa kwake. Ma carbide owonjezeredwa ndi monga tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC), niobium carbide (NbC), ndi zina zotero, ndipo cobalt (Co) ndiye gawo lodziwika bwino la chomangira chachitsulo.

Carbide yopangidwa ndi simenti yochokera ku titanium carbonitride makamaka imakhala ndi TiC (ena yokhala ndi ma carbide ena kapena ma nitride owonjezeredwa), yokhala ndi molybdenum (Mo) ndi nickel (Ni) ngati magawo omangira zitsulo omwe amagwiritsidwa ntchito kwambiri.

Kutengera ndi kukula kwa tirigu, carbide yopangidwa ndi simenti ikhoza kugawidwa m'magulu otsatirawa:

Carbide wamba wopangidwa ndi simenti

Carbide yopangidwa ndi simenti yabwino

Carbide yopangidwa ndi simenti ya ultrafine

Malinga ndi GB/T 2075—2007, zizindikiro za zilembo ndi izi:

HW: Carbide yosaphimbidwa ndi simenti makamaka yokhala ndi tungsten carbide (WC) yokhala ndi kukula kwa tirigu wa ≥1μm

HF: Carbide yosaphimbidwa ndi simenti makamaka yokhala ndi tungsten carbide (WC) yokhala ndi kukula kwa tirigu wa <1μm

HT: Carbide yosaphimbidwa yokhala ndi titanium carbide (TiC) kapena titanium nitride (TiN) kapena zonse ziwiri (zotchedwanso cermet)

HC: Ma carbide opangidwa ndi simenti omwe atchulidwa pamwambapa okhala ndi zokutira

Bungwe la International Organisation for Standardization (ISO) limagawa kudula ma carbide okhala ndi simenti m'magulu atatu:

Kalasi ya K (K10 mpaka K40):

Chofanana ndi kalasi ya YG yaku China (yopangidwa makamaka ndi WC-Co)

Kalasi ya P (P01 mpaka P50):

Chofanana ndi kalasi ya YT yaku China (yopangidwa makamaka ndi WC-TiC-Co)

Kalasi ya M (M10 mpaka M40):

Chofanana ndi kalasi ya YW yaku China (yopangidwa makamaka ndi WC-TiC-TaC(NbC)-Co)

Magiredi a gulu lililonse amaimiridwa ndi nambala pakati pa 01 ndi 50, kusonyeza mndandanda wa ma alloys kuyambira kuuma kwambiri mpaka kulimba kwambiri, kuti asankhidwe m'njira zosiyanasiyana zodulira ndi mikhalidwe yopangira zinthu zosiyanasiyana. Ngati kuli kofunikira, khodi yapakati ikhoza kuyikidwa pakati pa ma code awiri oyandikana, monga P15 pakati pa P10 ndi P20, kapena K25 pakati pa K20 ndi K30, koma osapitirira limodzi. Muzochitika zapadera, khodi ya gulu la P01 ikhoza kugawidwanso powonjezera nambala ina yolekanitsidwa ndi mfundo ya decimal, monga P01.1, P01.2, ndi zina zotero, kuti adziwitse bwino kukana kwa kuwonongeka ndi kulimba kwa zipangizo zomaliza ntchito.

Kugwira Ntchito kwa Zida za Simenti ya Carbide

1. Kulimba Carbide yokhala ndi simenti ili ndi ma carbide olimba ambiri (monga WC, TiC), zomwe zimapangitsa kuti kulimba kwake kukhale kwakukulu kwambiri kuposa kwa zipangizo zachitsulo zothamanga kwambiri. Kulimba kwa carbide yokhala ndi simenti kukakhala kwakukulu, kumateteza bwino kuwonongeka kwake, komwe nthawi zambiri kumakhala kwakukulu kwambiri kuposa kwa chitsulo chothamanga kwambiri.

Pamene cobalt binder phase ili yokwera, kuuma kwa alloy kumachepa.

Popeza TiC ndi yolimba kuposa WC, ma alloy a WC-TiC-Co ali ndi kuuma kwakukulu kuposa ma alloy a WC-Co. TiC ikachuluka, kuuma kwake kumakhala kwakukulu.

Kuwonjezera TaC ku WC-Co alloys kumawonjezera kuuma ndi pafupifupi 40 mpaka 100 HV; kuwonjezera NbC kumawonjezera ndi 70 mpaka 150 HV.

2. Mphamvu Mphamvu yopindika ya carbide yopangidwa ndi simenti ndi pafupifupi 1/3 mpaka 1/2 ya zipangizo zachitsulo zothamanga kwambiri.

Cobalt ikachuluka, mphamvu ya aloyi imakwera.

Ma alloys okhala ndi TiC ali ndi mphamvu zochepa kuposa omwe alibe TiC; TiC ikachuluka, mphamvu yake imakhala yochepa.

Kuwonjezera TaC ku WC-TiC-Co cemented carbide kumawonjezera mphamvu yake yopindika komanso kumawonjezera kwambiri kukana kwamakono ku chipsying ndi breakage. Pamene kuchuluka kwa TaC kukuchulukirachulukira, mphamvu ya kutopa imakulanso.

Mphamvu yokakamiza ya carbide yopangidwa ndi simenti ndi yokwera ndi 30% mpaka 50% kuposa ya chitsulo chothamanga kwambiri.

3. KulimbaKulimba kwa carbide yopangidwa ndi simenti ndi kotsika kwambiri kuposa kwa chitsulo chothamanga kwambiri.

Ma alloys okhala ndi TiC ali ndi kulimba kochepa kuposa omwe alibe TiC; pamene kuchuluka kwa TiC kumawonjezeka, kulimba kumachepa.

Mu ma alloys a WC-TiC-Co, kuwonjezera kuchuluka koyenera kwa TaC kumatha kuwonjezera kulimba ndi pafupifupi 10% pamene kukupitirizabe kukana kutentha ndi kukana kukalamba.

Chifukwa cha kulimba kwake kochepa, carbide yopangidwa ndi simenti si yoyenera malo okhala ndi mphamvu kapena kugwedezeka kwamphamvu, makamaka pa liwiro lochepa pomwe kumamatira ndi kusweka kumakhala koopsa kwambiri.

4. Kapangidwe ka Thupi la Kutentha Kayendetsedwe ka kutentha ka carbide yopangidwa ndi simenti ndi kokwera pafupifupi nthawi ziwiri kapena zitatu kuposa kachitsulo chothamanga kwambiri.

Popeza mphamvu ya kutentha ya TiC ndi yotsika kuposa ya WC, ma alloy a WC-TiC-Co ali ndi mphamvu yotsika ya kutentha kuposa ma alloy a WC-Co. TiC ikachuluka, mphamvu ya kutentha imakhala yotsika.

5. Kukana Kutentha Carbide yopangidwa ndi simenti imakhala ndi kukana kutentha kwambiri kuposa chitsulo champhamvu kwambiri ndipo imatha kudula pa 800 mpaka 1000°C ndi kukana bwino kusintha kwa pulasitiki kutentha kwambiri.

Kuonjezera TiC kumawonjezera kuuma kwa kutentha kwambiri. Popeza kutentha kwa TiC kofewa kuli kokwera kuposa kwa WC, kuuma kwa ma alloy a WC-TiC-Co kumachepa pang'onopang'ono ndi kutentha kuposa ma alloy a WC-Co. TiC ikachuluka komanso cobalt yochepa, kuchepa kwake kumakhala kochepa.

Kuwonjezera TaC kapena NbC (yomwe kutentha kwake kumafewa kwambiri kuposa TiC) kumawonjezera kuuma ndi mphamvu pa kutentha kwambiri.

6. Katundu Wotsutsana ndi Kumatira Kutentha kwa kumatira kwa carbide yolumikizidwa ndi simenti ndi kwakukulu kuposa kwa chitsulo chothamanga kwambiri, zomwe zimapangitsa kuti ikhale yolimba kwambiri kuti isamamatire.

Kutentha kwa Cobalt komwe kumamatira ndi chitsulo kumakhala kotsika kwambiri kuposa kwa WC; pamene kuchuluka kwa cobalt kumawonjezeka, kutentha kwa kumamatira kumachepa.

Kutentha kwa kumatirira kwa TiC kuli kokwera kuposa kwa WC, kotero ma alloy a WC-TiC-Co ali ndi kutentha kwakukulu komatirira (pafupifupi 100°C kuposa) kuposa ma alloy a WC-Co. TiO2 yopangidwa kutentha kwambiri panthawi yodula imachepetsa kumatirira.

TaC ndi NbC zili ndi kutentha kolimba kwambiri kuposa TiC, zomwe zimapangitsa kuti zinthu zisamatirire. Kugwirizana kwa TaC ndi zinthu zogwirira ntchito ndi kochepa kwambiri poyerekeza ndi magawo khumi a WC.

7. Kukhazikika kwa MankhwalaKukana kutopa kwa zida za carbide zomangidwa ndi simenti kumagwirizana kwambiri ndi kukhazikika kwawo kwakuthupi ndi kwa mankhwala pa kutentha kogwira ntchito.

Kutentha kwa okosijeni kwa carbide yopangidwa ndi simenti ndi kwakukulu kuposa kwa chitsulo chothamanga kwambiri.

Kutentha kwa okosijeni kwa TiC kumakhala kwakukulu kwambiri kuposa kwa WC, kotero ma alloy a WC-TiC-Co amapeza kulemera kochepa kwa okosijeni kutentha kwambiri kuposa ma alloy a WC-Co; TiC ikakhala yochuluka, kukana okosijeni kumakhala kolimba.

Kutentha kwa okosijeni kwa TaC nakonso kuli kokwera kuposa kwa WC, ndipo ma alloy okhala ndi TaC ndi NbC athandiza kwambiri kukana okosijeni kutentha kwambiri. Komabe, kuchuluka kwa cobalt kumapangitsa okosijeni kukhala kosavuta.

Chifukwa Chiyani Sankhani Chengduhuaxin Carbide?

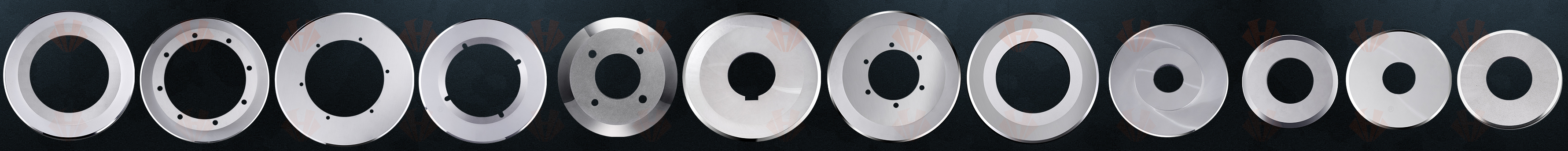

Chengduhuaxin Carbide imadziwika bwino pamsika chifukwa cha kudzipereka kwake ku khalidwe ndi zatsopano. Mabala awo a tungsten carbide ndi masamba a tungsten carbide odulidwa amapangidwa kuti azigwira ntchito bwino kwambiri, kupatsa ogwiritsa ntchito zida zomwe zimadula bwino komanso moyenera ngakhale atakhala ndi zovuta zogwiritsidwa ntchito m'mafakitale. Poganizira kwambiri kulimba komanso kugwira ntchito bwino, masamba a Chengduhuaxin Carbide odulidwa amapereka yankho labwino kwambiri kwa mafakitale omwe amafuna zida zodulira zodalirika.

CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ndi kampani yogulitsa zinthu zaukadaulo komanso yopanga zinthu zatsopano.zinthu za tungsten carbide,monga mipeni yopangira carbide yopangira matabwa, carbidemipeni yozungulirachifukwa chandodo zodulira fodya ndi ndudu, mipeni yozungulira zodulira makatoni okhala ndi corugat,masamba atatu oboola/masamba opindika zopakira, tepi, kudula filimu yopyapyala, masamba odulira ulusi amakampani opanga nsalu ndi zina zotero.

Ndi chitukuko cha zaka zoposa 25, zinthu zathu zatumizidwa ku US A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia ndi zina zotero. Ndi khalidwe labwino kwambiri komanso mitengo yopikisana, Khama lathu logwira ntchito komanso kuyankha kwathu kwavomerezedwa ndi makasitomala athu. Ndipo tikufuna kukhazikitsa ubale watsopano wamalonda ndi makasitomala atsopano.

Lumikizanani nafe lero ndipo mudzasangalala ndi ubwino wa zinthu zathu zabwino komanso ntchito zabwino!

Mafunso ofala kwa makasitomala ndi mayankho a Huaxin

Zimenezo zimadalira kuchuluka kwake, nthawi zambiri masiku 5-14. Monga wopanga masamba a mafakitale, Huaxin Cement Carbide imakonza kupanga kwake potengera maoda ndi zopempha za makasitomala.

Kawirikawiri milungu itatu mpaka isanu ndi umodzi, ngati mupempha mipeni yamakina yokonzedwa mwamakonda kapena masamba a mafakitale omwe mulibe panthawi yogula. Pezani Sollex Purchase & Delivery Conditions apa.

Ngati mupempha mipeni yamakina yokonzedwa mwamakonda kapena masamba a mafakitale omwe mulibe panthawi yogula, pezani Sollex Purchase & Delivery Conditions.Pano.

Kawirikawiri T/T, Western Union...dipoziti choyamba, Maoda onse oyamba ochokera kwa makasitomala atsopano amalipidwa pasadakhale. Maoda ena amatha kulipidwa ndi invoice...Lumikizanani nafekudziwa zambiri

Inde, titumizireni uthenga, mipeni ya mafakitale imapezeka m'njira zosiyanasiyana, kuphatikizapo mipeni yozungulira pamwamba, mipeni yozungulira pansi, mipeni yokhala ndi mano ozungulira, mipeni yozungulira yoboola, mipeni yowongoka, mipeni ya guillotine, mipeni yolunjika, mipeni ya rectangle leza, ndi mipeni ya trapezoidal.

Kuti tikuthandizeni kupeza tsamba labwino kwambiri, Huaxin Cement Carbide ingakupatseni zitsanzo zingapo za masamba kuti muyesere popanga. Pa kudula ndi kusintha zinthu zosinthika monga filimu ya pulasitiki, zojambulazo, vinyl, pepala, ndi zina, timapereka masamba osinthira kuphatikiza masamba odulidwa ndi masamba a lezala okhala ndi mipata itatu. Titumizireni funso ngati mukufuna masamba a makina, ndipo tidzakupatsani chopereka. Zitsanzo za mipeni yopangidwa mwamakonda sizikupezeka koma mwalandiridwa kuti muyitanitse kuchuluka kochepa kwa oda.

Pali njira zambiri zomwe zingawonjezere moyo wa mipeni yanu yamakampani ndi masamba omwe alipo. Lumikizanani nafe kuti mudziwe momwe kulongedza bwino mipeni yamakina, momwe imasungidwira, chinyezi ndi kutentha kwa mpweya, ndi zokutira zina zingatetezere mipeni yanu ndikusunga magwiridwe antchito ake odulira.

Nthawi yotumizira: Julayi-23-2025