Chipangizo chopangidwa ndi alloy chopangidwa ndi chitsulo cholimba chopangidwa ndi chitsulo chosagwira ntchito ndi chitsulo chomangira pogwiritsa ntchito njira ya ufa. Carbide yopangidwa ndi simenti ili ndi zinthu zabwino kwambiri monga kuuma kwambiri, kukana kuwonongeka, mphamvu yabwino ndi kulimba, kukana kutentha ndi dzimbiri, makamaka kuuma kwake kwakukulu ndi kukana kuwonongeka, komwe sikunasinthe ngakhale kutentha kwa 500 °C, kumakhalabe kuuma kwambiri pa 1000℃. Carbide imagwiritsidwa ntchito kwambiri ngati zida, monga zida zosinthira, zodulira mphero, zopukutira, zobowola, zida zobowola, ndi zina zotero, podula chitsulo chosungunuka, zitsulo zopanda chitsulo, mapulasitiki, ulusi wa mankhwala, graphite, galasi, miyala ndi chitsulo wamba, ndipo ingagwiritsidwenso ntchito podula zinthu zovuta kugwiritsa ntchito makina monga chitsulo chosagwira kutentha, chitsulo chosapanga dzimbiri, chitsulo cha manganese wambiri, chitsulo cha zida, ndi zina zotero. Liwiro lodulira zida zatsopano za carbide tsopano ndi nthawi mazana ambiri kuposa chitsulo cha kaboni.

Kugwiritsa ntchito carbide yopangidwa ndi simenti

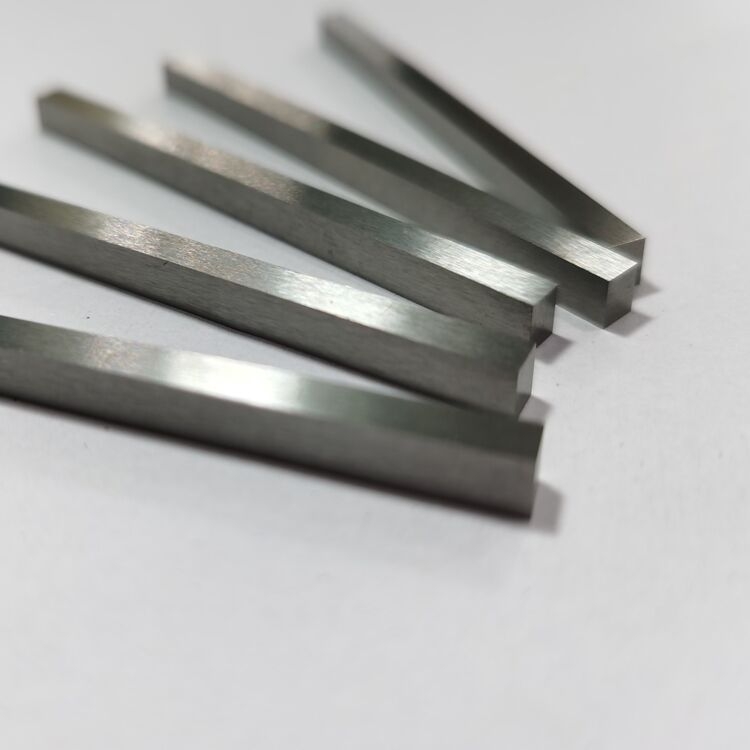

(1) Zida zogwiritsira ntchito

Carbide ndi chida chachikulu kwambiri chomwe chingagwiritsidwe ntchito popanga zida zozungulira, zodulira mphero, zopukutira, zobowolera, ndi zina zotero. Pakati pawo, tungsten-cobalt carbide ndi yoyenera kukonza zitsulo zachitsulo ndi zopanda chitsulo mwachangu komanso kukonza zinthu zopanda chitsulo, monga chitsulo chosungunuka, mkuwa wosungunuka, bakelite, ndi zina zotero; tungsten-titanium-cobalt carbide ndi yoyenera kukonza zitsulo zachitsulo monga chitsulo kwa nthawi yayitali. Kukonza zitsulo zachitsulo. Pakati pa zinthu zofanana, zomwe zili ndi cobalt yambiri ndizoyenera kukonza zinthu zopanda chitsulo, ndipo zomwe zili ndi cobalt yochepa ndizoyenera kumaliza. Carbides zogwiritsidwa ntchito nthawi zonse zimakhala ndi moyo wautali kwambiri wokonza zinthu kuposa ma carbides ena okhala ndi simenti pazinthu zovuta kugwiritsa ntchito monga chitsulo chosapanga dzimbiri.

(2) Zinthu zopangidwa ndi nkhungu

Carbide yopangidwa ndi simenti imagwiritsidwa ntchito makamaka pa zinthu zozizira monga zinthu zozizira monga zinthu zozizira, zinthu zozizira, zinthu zozizira, ndi zinthu zozizira monga zinthu zozizira.

Ma carbide cold heading dies amafunika kuti akhale ndi mphamvu yolimba, kusweka, kutopa, kupindika komanso kukana kutopa pogwiritsa ntchito njira zogwirira ntchito zosagwira ntchito kapena kugwedezeka mwamphamvu. Ma grade a cobalt apakati komanso okwera komanso apakati komanso okhwima nthawi zambiri amagwiritsidwa ntchito, monga YG15C.

Kawirikawiri, ubale pakati pa kukana kuvala ndi kulimba kwa carbide yolimba ndi wotsutsana: kuwonjezeka kwa kukana kuvala kudzachepetsa kulimba, ndipo kuwonjezeka kwa kulimba kudzachepetsa kukana kuvala. Chifukwa chake, posankha magiredi a alloy, ndikofunikira kukwaniritsa zofunikira zinazake zogwiritsidwa ntchito malinga ndi chinthu chogwirira ntchito ndi momwe ntchito yogwirira ntchito imagwirira ntchito.

Ngati giredi yomwe mwasankha imayamba kusweka msanga komanso kuwonongeka ikagwiritsidwa ntchito, giredi yomwe ili ndi kulimba kwambiri iyenera kusankhidwa; ngati giredi yomwe mwasankhayo imayamba kuwonongeka msanga ikagwiritsidwa ntchito, giredi yomwe ili ndi kuuma kwambiri komanso kukana bwino kuwonongeka iyenera kusankhidwa. . Magiredi otsatirawa: YG15C, YG18C, YG20C, YL60, YG22C, YG25C Kuchokera kumanzere kupita kumanja, kuuma kumachepa, kukana kuwonongeka kumachepa, ndipo kulimba kumawonjezeka; m'malo mwake, zosiyana ndi izi.

(3) Zida zoyezera ndi zida zosatha ntchito

Carbide imagwiritsidwa ntchito popanga zolumikizira pamwamba zomwe sizingawonongeke komanso zida zoyezera, ma bearing olondola a zopukusira, mbale zowongolera ndi ndodo zowongolera za zopukusira zopanda pakati, pamwamba pa ma lathe ndi zida zina zopewera kuwonongeka.

Zitsulo zomangira nthawi zambiri zimakhala zitsulo za gulu la chitsulo, nthawi zambiri cobalt ndi nickel.

Popanga carbide yopangidwa ndi simenti, kukula kwa tinthu ta ufa wa zinthu zopangira zosankhidwa kumakhala pakati pa ma microns 1 ndi 2, ndipo kuyera kwake kumakhala kwakukulu kwambiri. Zipangizo zopangirazo zimasakanizidwa motsatira chiŵerengero chovomerezeka cha kapangidwe kake, ndipo mowa kapena zinthu zina zimawonjezeredwa ku kugaya konyowa mu mphero yonyowa kuti zisakanizidwe bwino ndikuphwanyidwa. Sefa chisakanizocho. Kenako, chisakanizocho chimaphwanyidwa, kukanidwa, ndikutenthedwa kutentha komwe kuli pafupi ndi malo osungunuka a chitsulo chomangira (1300-1500 °C), gawo lolimba ndi chitsulo chomangira zidzapanga eutectic alloy. Pambuyo pozizira, magawo olimba amagawidwa mu gridi yopangidwa ndi chitsulo chomangira ndipo amalumikizidwa kwambiri kuti apange chinthu cholimba. Kulimba kwa carbide yomangira kumadalira kuchuluka kwa gawo lolimba ndi kukula kwa tirigu, ndiko kuti, kuchuluka kwa gawo lolimba komanso tirigu wochepa, kulimba kwake kumakhala kwakukulu. Kulimba kwa carbide yomangira kumatsimikiziridwa ndi chitsulo chomangira. Kuchuluka kwa chitsulo chomangira, mphamvu yosinthasintha imakhala yayikulu.

Mu 1923, Schlerter wa ku Germany anawonjezera cobalt 10% mpaka 20% ku ufa wa tungsten carbide ngati chomangira, ndipo anapanga aloyi yatsopano ya tungsten carbide ndi cobalt. Kulimba kwake ndi kwachiwiri pambuyo pa diamondi. Carbide yoyamba yopangidwa ndi simenti. Podula chitsulo ndi chida chopangidwa ndi aloyi iyi, m'mphepete mwake mudzatha msanga, ndipo ngakhale m'mphepete mwake mudzasweka. Mu 1929, Schwarzkov ku United States anawonjezera kuchuluka kwa tungsten carbide ndi titanium carbide compound carbides ku kapangidwe koyambirira, zomwe zinapangitsa kuti chidacho chigwire bwino ntchito podula chitsulo. Ichi ndi chinthu china chomwe chinapambana m'mbiri ya chitukuko cha carbide yopangidwa ndi simenti.

Carbide yopangidwa ndi simenti ili ndi zinthu zambiri zabwino monga kuuma kwambiri, kukana kuvala, mphamvu yabwino ndi kulimba, kukana kutentha ndi dzimbiri, makamaka kuuma kwake kwambiri komanso kukana kuvala, komwe sikunasinthe ngakhale kutentha kwa 500 °C, kumakhalabe kuuma kwambiri pa 1000℃. Carbide imagwiritsidwa ntchito kwambiri ngati zida, monga zida zosinthira, zodulira mphero, zopukutira, zobowola, zida zobowola, ndi zina zotero, podula chitsulo chosungunuka, zitsulo zopanda chitsulo, mapulasitiki, ulusi wa mankhwala, graphite, galasi, miyala ndi chitsulo wamba, ndipo ingagwiritsidwenso ntchito podula zinthu zovuta kugwiritsa ntchito makina monga chitsulo chosagwira kutentha, chitsulo chosapanga dzimbiri, chitsulo cha manganese wambiri, chitsulo cha zida, ndi zina zotero. Liwiro lodulira zida zatsopano za carbide tsopano ndi nthawi mazana ambiri kuposa chitsulo cha kaboni.

Carbide ingagwiritsidwenso ntchito popanga zida zobowola miyala, zida zogobolera, zida zoyezera, zida zosatha, zopopera zitsulo, zoyikamo masilinda, ma bearing olondola, ma nozzles, zinyalala zachitsulo (monga ma waya ojambulira ma dies, ma bolt dies, ma nut dies, ndi mitundu yosiyanasiyana ya zomangira, magwiridwe antchito abwino kwambiri a carbide yolumikizidwa ndi simenti pang'onopang'ono adalowa m'malo mwa zinyalala zakale).

Pambuyo pake, kabati yophimbidwa ndi simenti inatulukanso. Mu 1969, dziko la Sweden linapanga bwino chida chophimbidwa ndi titanium carbide. Maziko a chidacho ndi tungsten-titanium-cobalt carbide kapena tungsten-cobalt carbide. Kukhuthala kwa chophimba cha titanium carbide pamwamba ndi ma microns ochepa chabe, koma poyerekeza ndi mtundu womwewo wa zida za alloy, Moyo wautumiki umakulitsidwa ndi nthawi zitatu, ndipo liwiro lodulira limawonjezeka ndi 25% mpaka 50%. M'zaka za m'ma 1970, m'badwo wachinayi wa zida zophimbidwa zinawonekera zodulira zipangizo zovuta kugwiritsa ntchito makina.

Kodi carbide yopangidwa ndi simenti imatsukidwa bwanji?

Carbide yopangidwa ndi simenti ndi chitsulo chopangidwa ndi ufa wa carbides ndi zitsulo zomangira za chitsulo chimodzi kapena zingapo zotsutsana.

Mmayiko opanga zinthu zatsopano

Pali mayiko opitilira 50 padziko lonse lapansi omwe amapanga carbide yopangidwa ndi simenti, ndipo kuchuluka kwake ndi 27,000-28,000t-. Opanga akuluakulu ndi United States, Russia, Sweden, China, Germany, Japan, United Kingdom, France, ndi zina zotero. Msika wa carbide wopangidwa ndi simenti padziko lonse lapansi uli wodzaza ndi zinthu zambiri. Mpikisano wamsika ndi woopsa kwambiri. Makampani opanga carbide yopangidwa ndi simenti ku China anayamba kupanga zinthu kumapeto kwa zaka za m'ma 1950. Kuyambira m'ma 1960 mpaka m'ma 1970, makampani opanga carbide yopangidwa ndi simenti ku China adakula mofulumira. Kumayambiriro kwa zaka za m'ma 1990, mphamvu yonse yopangira carbide yopangidwa ndi simenti ku China idafika 6000t, ndipo kuchuluka konse kwa carbide yopangidwa ndi simenti kudafika 5000t, yachiwiri ku Russia ndi United States, ili pa nambala 3 padziko lonse lapansi.

Chodulira cha WC

①Tungsten ndi cobalt simenti carbide

Zigawo zazikulu ndi tungsten carbide (WC) ndi binder cobalt (Co).

Gulu lake limapangidwa ndi "YG" ("cholimba ndi cobalt" mu Pinyin yaku China) ndi kuchuluka kwa kuchuluka kwa cobalt.

Mwachitsanzo, YG8 imatanthauza WCo yapakati = 8%, ndipo yotsalayo ndi tungsten-cobalt carbide ya tungsten carbide.

Mipeni ya TIC

②Tungsten-titanium-cobalt carbide

Zigawo zazikulu ndi tungsten carbide, titanium carbide (TiC) ndi cobalt.

Mtundu wake umapangidwa ndi "YT" ("wolimba, titaniyamu" zilembo ziwiri mu chiganizo cha Pinyin cha ku China) ndi kuchuluka kwa titaniyamu carbide.

Mwachitsanzo, YT15 imatanthauza WTi yapakati = 15%, ndipo yotsalayo ndi tungsten carbide ndi tungsten-titanium-cobalt carbide yokhala ndi cobalt yambiri.

Chida cha Tungsten Titanium Tantalum

③Tungsten-titanium-tantalum (niobium) carbide yopangidwa ndi simenti

Zigawo zazikulu ndi tungsten carbide, titanium carbide, tantalum carbide (kapena niobium carbide) ndi cobalt. Mtundu uwu wa carbide wopangidwa ndi simenti umatchedwanso general cemented carbide kapena universal cemented carbide.

Giredi yake imapangidwa ndi "YW" (chiyambi cha mawu achi China cha "hard" ndi "wan") komanso nambala yotsatizana, monga YW1.

Makhalidwe a magwiridwe antchito

Zoyikapo Zopangidwa ndi Carbide

Kulimba kwambiri (86 ~93HRA, kofanana ndi 69 ~81HRC);

Kuuma kwabwino kwa kutentha (mpaka 900 ~1000 ℃, kusunga 60HRC);

Kukana bwino kukanda.

Zipangizo zodulira makabati zimakhala zothamanga kwambiri nthawi 4 mpaka 7 kuposa chitsulo chothamanga kwambiri, ndipo nthawi ya zida zake ndi yokwera nthawi 5 mpaka 80. Popanga nkhungu ndi zida zoyezera, nthawi ya ntchito yake ndi yokwera nthawi 20 mpaka 150 kuposa ya chitsulo choyezera. Imatha kudula zipangizo zolimba pafupifupi 50HRC.

Komabe, kabodi yopangidwa ndi simenti ndi yofooka ndipo singathe kupangidwa ndi makina, ndipo n'kovuta kupanga zida zomangira zokhala ndi mawonekedwe ovuta. Chifukwa chake, masamba amitundu yosiyanasiyana nthawi zambiri amapangidwa, omwe amayikidwa pa thupi la chida kapena thupi la nkhungu mwa kuwotcherera, kulumikiza, kukanikiza makina, ndi zina zotero.

Mpiringidzo wooneka ngati wapadera

Kusakaniza

Kuumba simenti ya carbide ndi simenti ndiko kukanikiza ufawo mu billet, kenako kulowa mu uvuni wa simenti kuti utenthe kutentha kwina (kutentha kotentha), kuusunga kwa nthawi inayake (kusunga nthawi), kenako nkuuziziritsa kuti upeze zinthu za simenti ya carbide zokhala ndi makhalidwe ofunikira.

Njira yoyeretsera carbide yopangidwa ndi simenti ingagawidwe m'magawo anayi oyambira:

1: Pa gawo lochotsa chinthu chopangira ndi kuyikapo kale, thupi lophwanyika limasintha motere:

Kuchotsedwa kwa chopangira utomoni, ndi kutentha kwakukulu pagawo loyambirira la kupukuta, chopangira utomoni chimawola pang'onopang'ono kapena kuuma, ndipo thupi lopukuta limachotsedwa. Mtundu, kuchuluka ndi njira yopukuta zimasiyana.

Ma oxides omwe ali pamwamba pa ufa amachepa. Pa kutentha kwa sintering, hydrogen imatha kuchepetsa ma oxides a cobalt ndi tungsten. Ngati chopangiracho chachotsedwa mu vacuum ndikusiyidwa, carbon-oxygen reaction siili yolimba. Kupsinjika pakati pa tinthu ta ufa kumachotsedwa pang'onopang'ono, ufa wachitsulo womangirira umayamba kubwereranso ndikubwezeretsanso, kufalikira kwa pamwamba kumayamba kuchitika, ndipo mphamvu ya briquetting imawonjezeka.

2: Gawo lolimba lotentha (kutentha kwa 800℃–eutectic)

Pa kutentha kusanayambe kuwonekera kwa gawo lamadzimadzi, kuwonjezera pa kupitiriza njira ya gawo lapitalo, kuchitapo kanthu kwa gawo lolimba ndi kufalikira kumawonjezeka, kuyenda kwa pulasitiki kumawonjezeka, ndipo thupi lophwanyika limachepa kwambiri.

3: Gawo lothira madzi (kutentha kwa eutectic - kutentha kwa sintering)

Pamene gawo lamadzimadzi likuwonekera m'thupi losungunuka, kuchepa kwake kumatsirizika mwachangu, kutsatiridwa ndi kusintha kwa kristalo kuti apange kapangidwe koyambira ndi kapangidwe ka alloy.

4: Gawo lozizira (kutentha kwa kutentha - kutentha kwa chipinda)

Pa gawo ili, kapangidwe ndi kapangidwe ka gawo la alloy zimasinthasintha pang'ono ndi mikhalidwe yosiyanasiyana yoziziritsira. Mbali imeneyi ingagwiritsidwe ntchito kutentha carbide yopangidwa ndi simenti kuti ikonze mawonekedwe ake akuthupi komanso amakina.

Nthawi yotumizira: Epulo-11-2022