Chitsulo cha alloy chopangidwa ndi chitsulo cholimba chachitsulo chosakanizidwa ndi chitsulo chomangira kupyolera muzitsulo za ufa.Simenti carbide ali ndi mndandanda wa zinthu zabwino kwambiri monga kuuma mkulu, kukana kuvala, mphamvu zabwino ndi kulimba, kukana kutentha ndi dzimbiri kukana, makamaka kuuma kwake mkulu ndi kuvala kukana, amene amakhalabe kwenikweni osasintha ngakhale kutentha 500 ° C , akadali ndi kuuma kwakukulu pa 1000 ℃.Carbide chimagwiritsidwa ntchito monga zida zida, monga kutembenuza zida, odula mphero, planers, kubowola, zida wotopetsa, etc., kudula kuponyedwa chitsulo, zitsulo sanali achitsulo, mapulasitiki, ulusi mankhwala, graphite, galasi, mwala ndi zitsulo wamba, ndipo angagwiritsidwenso ntchito kudula Zida Zovuta ku makina monga zitsulo zosagwira kutentha, zitsulo zosapanga dzimbiri, zitsulo zamtengo wapatali za manganese, zitsulo zachitsulo, ndi zina zotero. Kuthamanga kwa zida zatsopano za carbide tsopano ndi mazana a zitsulo za carbon.

Kugwiritsa ntchito simenti carbide

(1) Zida zothandizira

Carbide ndiye kuchuluka kwakukulu kwa zida zomwe zingagwiritsidwe ntchito popangira zida zosinthira, odulira mphero, ma planer, zobowolera, etc. Pakati pawo, tungsten-cobalt carbide ndi yoyenera kwachidule chachidule chachitsulo chachitsulo ndi zitsulo zosakhala ndi chitsulo. zinthu zopanda zitsulo, monga chitsulo chosungunuka, mkuwa, bakelite, etc.;tungsten-titanium-cobalt carbide ndi yoyenera kukonzanso kwanthawi yayitali zitsulo zachitsulo monga chitsulo.Chip Machining.Pakati pa ma aloyi ofanana, omwe ali ndi cobalt ochulukirapo ndi oyenera kupanga makina ovuta, ndipo omwe ali ndi cobalt ochepa ndi oyenera kumaliza.Ma carbides opangidwa ndi simenti nthawi zambiri amakhala ndi moyo wautali kwambiri kuposa ma carbides ena opangidwa ndi simenti pazinthu zovuta kupanga monga chitsulo chosapanga dzimbiri.

(2) Zinthu za nkhungu

Carbide yokhala ndi simenti imagwiritsidwa ntchito kwambiri pakufa kozizira monga kuzizira kozizira, kubaya kozizira kumafa, kuzizira kozizira kumafa, ndipo pier yozizira imafa.

Carbide ozizira mutu umafa amafunikira kuti ukhale wolimba bwino, kulimba kwa fracture, mphamvu ya kutopa, mphamvu yopindika ndi kukana kwabwino kwa kuvala pansi pamikhalidwe yogwira ntchito yosamva kapena kukhudza mwamphamvu.Cobalt wapakatikati komanso wapamwamba komanso magiredi ang'onoang'ono komanso olimba ambewu amagwiritsidwa ntchito, monga YG15C.

Nthawi zambiri, mgwirizano pakati pa kukana kuvala ndi kulimba kwa simenti ya carbide ndi wotsutsana: kuwonjezeka kwa kukana kuvala kumabweretsa kuchepa kwa kulimba, ndipo kuwonjezereka kwamphamvu kudzatsogolera kuchepa kwa kukana kuvala.Chifukwa chake, posankha magiredi aloyi, ndikofunikira kukwaniritsa zofunikira zenizeni zogwiritsiridwa ntchito molingana ndi chinthu chopangira ndi kukonza magwiridwe antchito.

Ngati kalasi yosankhidwayo imakonda kusweka koyambirira komanso kuwonongeka pakagwiritsidwa ntchito, kalasi yokhala ndi kulimba kwambiri iyenera kusankhidwa;ngati kalasi yosankhidwayo imakonda kuvala koyambirira komanso kuwonongeka pakagwiritsidwa ntchito, kalasi yokhala ndi kuuma kwakukulu komanso kukana kuvala bwino iyenera kusankhidwa..Maphunziro otsatirawa: YG15C, YG18C, YG20C, YL60, YG22C, YG25C Kuchokera kumanzere kupita kumanja, kuuma kumachepa, kukana kuvala kumachepa, ndipo kulimba kumawonjezeka;m'malo mwake, zosiyana ndi zoona.

(3) Zida zoyezera ndi ziwalo zosagwira ntchito

Carbide imagwiritsidwa ntchito popanga zoyikapo pamwamba zosagwira ntchito ndi zida zoyezera, zonyamula zopukutira bwino, mbale zowongolera ndi ndodo zopukutira zopanda pakati, nsonga za lathes ndi zida zina zosamva kuvala.

Zitsulo zomangira nthawi zambiri zimakhala zitsulo zamagulu achitsulo, nthawi zambiri cobalt ndi faifi tambala.

Mukamapanga simenti ya carbide, kukula kwa tinthu tating'onoting'ono ta ufa wosankhidwa ndi pakati pa 1 ndi 2 microns, ndipo chiyero ndi chachikulu kwambiri.Zopangirazo zimayikidwa molingana ndi chiŵerengero chokhazikitsidwa, ndipo mowa kapena zofalitsa zina zimawonjezedwa pakupera konyowa mu mphero yonyowa kuti ikhale yosakanikirana ndi kupunthwa.Sieve osakaniza.Kenako, kusakaniza kumapangidwa ndi granulated, kukanikizidwa, ndikutenthedwa mpaka kutentha pafupi ndi malo osungunuka a zitsulo zomangira (1300-1500 ° C), gawo lolimba ndi zitsulo zomangira zimapanga alloy eutectic.Pambuyo pozizira, magawo owuma amagawidwa mu gridi yopangidwa ndi zitsulo zomangira ndipo zimagwirizanitsidwa kwambiri kuti zikhale zolimba.Kuuma kwa simenti carbide kumadalira kuuma gawo zili ndi kukula kwa tirigu, ndiko kuti, kukwezeka kwa gawo lowumitsidwa ndi kulimba kwa mbewu, kumapangitsanso kuuma kwake.Kulimba kwa carbide yopangidwa ndi simenti kumatsimikiziridwa ndi zitsulo zomangira.Kukwera kwazitsulo zomangira zitsulo, kumapangitsanso mphamvu yosinthasintha.

Mu 1923, Schlerter wa ku Germany anawonjezera 10% mpaka 20% ya cobalt ku tungsten carbide ufa monga binder, ndipo anapanga alloy yatsopano ya tungsten carbide ndi cobalt.Kuuma kwake ndi kwachiwiri kwa diamondi.Carbide yoyamba yopangidwa ndi simenti.Podula zitsulo ndi chida chopangidwa ndi alloy iyi, nsonga yodula idzatha mofulumira, ndipo ngakhale m'mphepete mwake idzasweka.Mu 1929, Schwarzkov ku United States anawonjezera kuchuluka kwa tungsten carbide ndi titaniyamu carbide pawiri carbides kuti zikuchokera pachiyambi, amene bwino ntchito chida mu kudula zitsulo.Ichi ndi kupambana kwina m'mbiri ya chitukuko cha simenti ya carbide.

Simenti carbide ali ndi mndandanda wa zinthu zabwino kwambiri monga kuuma mkulu, kukana kuvala, mphamvu zabwino ndi kulimba, kukana kutentha ndi dzimbiri kukana, makamaka kuuma kwake mkulu ndi kuvala kukana, amene amakhalabe kwenikweni osasintha ngakhale kutentha 500 ° C , akadali ndi kuuma kwakukulu pa 1000 ℃.Carbide chimagwiritsidwa ntchito monga zida zida, monga kutembenuza zida, odula mphero, planers, kubowola, zida wotopetsa, etc., kudula kuponyedwa chitsulo, zitsulo sanali achitsulo, mapulasitiki, ulusi mankhwala, graphite, galasi, mwala ndi zitsulo wamba, ndipo angagwiritsidwenso ntchito kudula Zida Zovuta ku makina monga zitsulo zosagwira kutentha, zitsulo zosapanga dzimbiri, zitsulo zamtengo wapatali za manganese, zitsulo zachitsulo, ndi zina zotero. Kuthamanga kwa zida zatsopano za carbide tsopano ndi mazana a zitsulo za carbon.

Carbide itha kugwiritsidwanso ntchito popanga zida zobowola miyala, zida zamigodi, zida zobowola, zida zoyezera, zida zosagwira ntchito, zotayira zitsulo, zomangira ma cylinder, mayendedwe olondola, ma nozzles, nkhungu zachitsulo (monga kujambula waya kumafa, bawuti imafa, mtedza umafa. , ndi zisankho zosiyanasiyana zomangira, ntchito yabwino kwambiri ya carbide yomangidwa pang'onopang'ono idalowa m'malo mwa zitsulo zam'mbuyomu).

Pambuyo pake, carbide yokutidwa ndi simenti idatulukanso.Mu 1969, dziko la Sweden linapanga bwino chida cha titanium carbide.Pansi pa chidacho ndi tungsten-titanium-cobalt carbide kapena tungsten-cobalt carbide.Makulidwe a titaniyamu carbide ❖ kuyanika pamwamba ndi ma microns ochepa, koma poyerekeza ndi mtundu womwewo wa aloyi zida, Moyo utumiki anawonjezera ndi 3, ndi kudula liwiro chawonjezeka ndi 25% mpaka 50%.M'zaka za m'ma 1970, m'badwo wachinayi wa zida zokutira zidawonekera zodulira zida zovuta kupanga.

Kodi sintered carbide sintered bwanji?

Cemented carbide ndi zitsulo zopangidwa ndi ufa wa carbides ndi zitsulo zomangira zachitsulo chimodzi kapena zingapo zokana.

Mmaiko okulirapo

Pali mayiko opitilira 50 padziko lapansi omwe amapanga simenti ya carbide, yomwe ili ndi 27,000-28,000t-.Opanga kwambiri ndi United States, Russia, Sweden, China, Germany, Japan, United Kingdom, France, ndi zina zotero. Msika wa carbide wopangidwa ndi simenti wapadziko lonse lapansi ndiwodzaza., mpikisano wamsika ndi woopsa kwambiri.Makampani opanga simenti a carbide aku China adayamba kupanga chakumapeto kwa zaka za m'ma 1950.Kuyambira m’ma 1960 mpaka m’ma 1970, makampani opanga simenti ku China anakula mofulumira.Kumayambiriro kwa zaka za m'ma 1990, kuchuluka kwa kupanga kwa carbide ku China kunafika pa 6000t, ndipo chiwerengero cha carbide chopangidwa ndi simenti chinafika 5000t, chachiwiri ku Russia ndi United States, chili pachitatu padziko lonse lapansi.

WC wodula

① Tungsten ndi cobalt cemented carbide

Zigawo zazikuluzikulu ndi tungsten carbide (WC) ndi binder cobalt (Co).

Gulu lake limapangidwa ndi "YG" ("hard and cobalt" mu Chinese Pinyin) ndi kuchuluka kwa cobalt pafupifupi.

Mwachitsanzo, YG8 amatanthauza pafupifupi WCo = 8%, ndipo ena onse ndi tungsten-cobalt carbide ya tungsten carbide.

TIC mipeni

②Tungsten-titanium-cobalt carbide

Zigawo zazikuluzikulu ndi tungsten carbide, titanium carbide (TiC) ndi cobalt.

Gulu lake limapangidwa ndi "YT" ("hard, titanium" zilembo ziwiri mu Chinese Pinyin prefix) ndi avareji ya titanium carbide.

Mwachitsanzo, YT15 imatanthauza pafupifupi WTi = 15%, ndipo yotsalayo ndi tungsten carbide ndi tungsten-titanium-cobalt carbide yokhala ndi cobalt.

Chida cha Tungsten Titanium Tantalum

③ Tungsten-titanium-tantalum (niobium) simenti carbide

Zigawo zazikuluzikulu ndi tungsten carbide, titanium carbide, tantalum carbide (kapena niobium carbide) ndi cobalt.Carbide yamtundu wotereyi imatchedwanso general cemented carbide kapena universal cemented carbide.

Gawo lake limapangidwa ndi "YW" (chiyambi cha fonitiki yaku China cha "hard" ndi "wan") kuphatikiza nambala yotsatizana, monga YW1.

Makhalidwe amachitidwe

Carbide Welded Insert

Kuuma kwakukulu (86~93HRA, kofanana ndi 69~81HRC);

Kuuma kwabwino kwamafuta (mpaka 900~1000 ℃, sungani 60HRC);

Kukana bwino kwa abrasion.

Zida zodulira Carbide ndi 4 mpaka 7 mwachangu kuposa chitsulo chothamanga kwambiri, ndipo moyo wa chida ndi nthawi 5 mpaka 80.Kupanga zisankho ndi zida zoyezera, moyo wautumiki ndi nthawi 20 mpaka 150 kuposa chitsulo cha alloy tool.Itha kudula zida zolimba pafupifupi 50HRC.

Komabe, carbide yopangidwa ndi simenti ndi yonyezimira ndipo sangathe kupangidwa ndi makina, ndipo n'zovuta kupanga zida zofunikira ndi maonekedwe ovuta.Choncho, masamba a mawonekedwe osiyanasiyana nthawi zambiri amapangidwa, omwe amaikidwa pa chida thupi kapena nkhungu thupi ndi kuwotcherera, kugwirizana, makina clamping, etc.

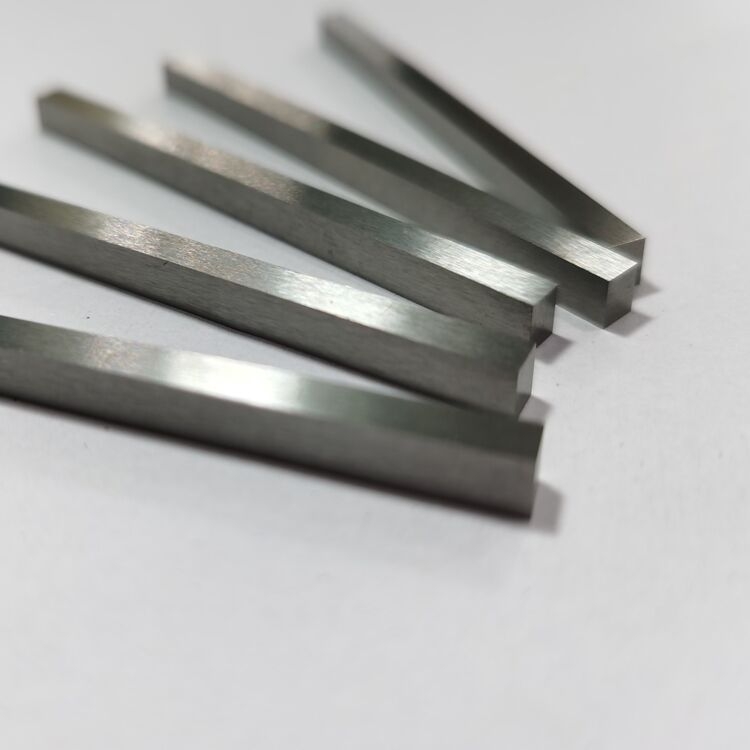

Bar yooneka ngati yapadera

Sintering

Cemented carbide sintering akamaumba ndi kukanikiza ufa mu billet, ndiyeno kulowa sintering ng'anjo kutentha kwa kutentha kwina (kutentha sintering), kusunga kwa nthawi inayake (kugwira nthawi), ndiyeno kuziziziritsa izo pansi kupeza simenti. carbide ndi zinthu zofunika.

Njira yopangira simenti ya carbide ikhoza kugawidwa m'magawo anayi:

1: Mugawo lochotsa chopangira ndi pre-sintering, thupi losasinthika limasintha motere:

Kuchotsedwa kwa wopangira jekeseni, ndi kuwonjezeka kwa kutentha mu gawo loyamba la sintering, wopangirayo amawola pang'onopang'ono kapena amawotcha, ndipo thupi la sintered limachotsedwa.Mtundu, kuchuluka ndi njira ya sintering ndizosiyana.

Ma oxides pamwamba pa ufa amachepetsedwa.Pa kutentha kwa sintering, haidrojeni imatha kuchepetsa ma oxide a cobalt ndi tungsten.Ngati chopangiracho chichotsedwa mu vacuum ndi sintered, mpweya wa okosijeni umakhala wopanda mphamvu.Kukhudzana ndi nkhawa pakati pa particles ufa pang'onopang'ono kuthetsedwa, chitsulo chomangira ufa chimayamba kuchira ndi kukonzanso, kufalikira kwapamwamba kumayamba kuchitika, ndipo mphamvu ya briquetting imakhala bwino.

2: siteji yolimba ya sintering (800 ℃ - kutentha kwa eutectic)

Pa kutentha kusanayambe kuwonekera kwa gawo lamadzimadzi, kuwonjezera pa kupitiriza ndondomeko ya siteji yapitayi, njira yolimba-gawo ndi kufalikira kumawonjezereka, kutuluka kwa pulasitiki kumawonjezeka, ndipo thupi la sintered limachepa kwambiri.

3: siteji yamadzimadzi sintering (kutentha kwa eutectic - kutentha kwa sintering)

Pamene gawo lamadzimadzi likuwonekera mu thupi lopangidwa ndi sintered, shrinkage imatsirizidwa mwamsanga, ndikutsatiridwa ndi kusintha kwa crystallographic kuti apange maziko ndi mapangidwe a alloy.

4: Gawo lozizira (kutentha kwa sintering - kutentha kwa chipinda)

Pakadali pano, kapangidwe kake ndi gawo la aloyiyo zimakhala ndi zosintha zina ndi kuzizira kosiyanasiyana.Mbali imeneyi angagwiritsidwe ntchito kutentha simenti carbide kusintha thupi ndi makina ake.

Nthawi yotumiza: Apr-11-2022